Have you ever wondered how your favorite spirit, vodka, is made? The process is both fascinating and intricate, even if you aren't a professional distiller. As the creators of Vodka Doctors, everything related to this popular drink is our passion. In this article, we'll guide you through the vodka-making process, including the ingredients, steps, techniques, and even a realistic example of producing vodka. Let's dive into the world of vodka and get a better understanding of how this versatile spirit comes to life.

Best Budget Vodkas Ranked

How Do.You Make Vodka Table of Contents

Looking For The Best Vodka? You'll Love These Vodka Guides...

Ingredients and Raw Materials

Vodka can be made from various ingredients, including grains, potatoes, sugar beets, and molasses. Each ingredient creates a different flavor profile, so the choice comes down to personal preference or regional availability. Common grains used to make vodka include wheat, rye, and corn. Here's a look at these ingredients and their impact on vodka taste:

- Wheat: Vodka made from wheat tends to be smooth and sweet with a slightly creamy texture.

- Rye: Rye-based vodka has a bolder, more robust flavor with a hint of spice.

- Corn: Corn-based vodka is known for being sweet, light, and smooth. It's perfect for sipping on its own or in a subtle cocktail.

- Potatoes: Potato vodka is typically richer in taste and texture, with an earthy flavor profile and a creamy mouthfeel.

The Vodka Production Process

Producing vodka involves several key steps, including fermentation, distillation, and filtration. Let's take a closer look at each stage:

1. Fermentation

The first step in making vodka is fermenting the chosen raw materials. This involves converting the starches and sugars in the ingredients into alcohol through the use of enzymes and yeast. The fermentation process typically takes around two to five days, depending on the temperature and the type of yeast used.

2. Distillation

Next comes the distillation process, which removes impurities and increases the alcohol content of the liquid. The fermented liquid is heated, causing the alcohol to evaporate and separate from the water and other solids. The alcohol vapors are collected and cooled back into a liquid, concentrating the alcohol content. This process may be repeated multiple times to further purify and concentrate the vodka.

3. Filtration

After distillation, the vodka is filtered to remove any remaining impurities and to refine its taste. There are various filtration methods used by different producers, including charcoal, limestone, and quartz sand. Some vodka brands also use additional steps like resting or adding flavorings after filtration to create a unique taste and texture for their product.

4. Dilution and Bottling

Finally, the concentrated vodka is diluted with water to reach the desired alcohol content, typically around 40% ABV (alcohol by volume). Then, the vodka is bottled, labeled, and packed for shipment to retailers and consumers.

How Do.You Make Vodka Example:

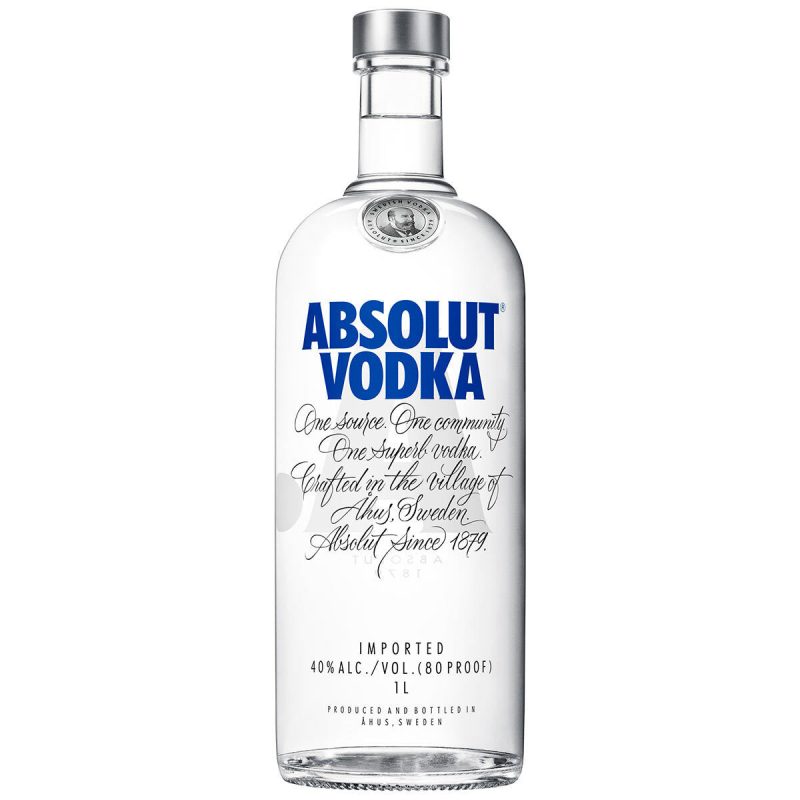

To provide a better understanding of the vodka-making process, let's take a look at a popular wheat-based vodka brand like Absolut. Starting with high-quality wheat, Absolut ferments the starches into alcohol using a carefully selected yeast strain. The fermented liquid is then distilled multiple times in a continuous still, producing a highly concentrated spirit. Absolut uses charcoal and additional distillations to filter the vodka, resulting in a clean, smooth taste. The vodka is then diluted with water to reach the standard 40% ABV and bottled for distribution.

Now that you know the process of making vodka, you can better appreciate the craftsmanship and passion that goes into producing this versatile spirit. Whether you're a casual vodka drinker or a vodka connoisseur, we hope you enjoyed this in-depth look at how vodka is made. If you enjoyed this article, share it with friends and continue exploring the world of vodka through our other informative guides on Vodka Doctors. Cheers!

Frequently Asked Questions

What is vodka made from?

Vodka can be made from a variety of ingredients that contain fermentable sugars or starches, such as grains (like wheat or rye), potatoes, grapes, or corn. Once fermented, these materials are distilled to produce a clear, high-purity spirit.

What is the basic process of making vodka?

The basic process of making vodka involves four main steps: fermentation, distillation, filtration, and dilution. First, the base ingredients are fermented with yeast to convert sugars into alcohol. Then, the alcohol is distilled to increase its purity. After that, it's often filtered through charcoal or other materials to remove impurities and finally diluted with water to reach the desired alcohol content.

How does distillation work?

Distillation is the process of heating the fermented liquid to a temperature that vaporizes the alcohol while leaving most impurities behind. The alcohol vapor is then condensed back into liquid form and collected, with this process often repeated several times to increase purity and alcohol content.

Is homemade vodka safe to drink?

Homemade vodka can be safe to drink if made properly. However, it is important to follow a trusted recipe and use the right equipment because improper distillation can lead to the presence of harmful impurities like methanol. Always be aware of the laws in your area regarding home distillation, as it is illegal in many places without proper permits.

Can you flavor vodka at home?

Yes, you can flavor vodka at home using a variety of ingredients such as fruits, herbs, and spices. The process usually involves infusing the vodka with the flavoring agents over a period of time. Filtering out the ingredients after infusion gives you a personalized vodka flavor.

What is the role of yeast in vodka production?

Yeast plays a critical role in vodka production by converting fermentable sugars from the base ingredients into ethanol and carbon dioxide during the fermentation process. The type of yeast used can affect the speed of fermentation and the flavor of the final product.

Does the water quality matter when making vodka?

Yes, water quality is crucial when making vodka because water is used in both the fermentation and the dilution processes. The use of pure, clean water without impurities can greatly affect the taste and quality of the final product.

What is the ideal alcohol content of vodka?

The ideal alcohol content of vodka is typically around 40% alcohol by volume (ABV), though it can range from 35% to 50% ABV depending on brand and location. Vodka standards may vary by country.

How long does it take to ferment vodka?

The fermentation process for vodka typically ranges from 1 to 2 weeks, depending on factors such as the ingredients used, temperature, and the concentration of yeast. Complete fermentation is crucial before moving on to distillation.

What is the difference between filtered and unfiltered vodka?

Filtered vodka has been passed through substances such as charcoal to remove impurities and refine its flavor. Unfiltered vodka skips this step and may have a more robust taste, depending on the raw materials and distillation process used.

How important is the distillation process in making quality vodka?

The distillation process is very important in making quality vodka, as it purifies the fermented alcohol and helps remove unwanted flavors and impurities. The number and type of distillations can greatly influence the smoothness and purity of the vodka.

Can gluten-free vodka be made from grains?

Gluten-free vodka can indeed be made from grains, as the distillation process should remove gluten proteins. However, some people with severe gluten sensitivities may opt for vodka made from non-grain sources like potatoes or grapes.

How can you tell when vodka fermentation is complete?

Fermentation is typically considered complete when bubbles stop rising to the surface, indicating that the yeast has consumed all fermentable sugars. This can also be verified by using a hydrometer to measure the liquid's specific gravity, confirming the cessation of sugar conversion into alcohol.

Is it necessary to age vodka?

Unlike spirits such as whiskey or rum, vodka is generally not aged and can be consumed soon after production. However, some premium vodkas may be rested for a short period to allow flavors to meld, especially if it is a flavored or infused vodka.

What are the legal requirements for producing vodka commercially?

The legal requirements for producing vodka commercially vary greatly by country and region. Generally, producers must obtain proper distilling licenses, adhere to health and safety regulations, meet labeling guidelines, and often pass quality inspections to ensure their product is safe for consumption.

Is it possible to distill vodka multiple times, and what does this achieve?

Vodka can be distilled multiple times, with each distillation generally resulting in higher purity and a smoother taste. Some brands tout multiple distillations as a selling point, though the benefits may diminish after a certain number of distillations.

How does the proof of vodka relate to its alcohol content?

The proof of vodka is a measure of its alcohol content, with one proof being equal to 0.5% alcohol by volume (ABV) in the United States. Hence, an 80-proof vodka contains 40% ABV. In other countries, the proofing system may differ.

Can vodka be organic?

Yes, vodka can be labeled as organic if it is made from ingredients that are certified as organic, meaning they are grown without synthetic pesticides or fertilizers, and the production process adheres to the standards set for organic products.

Are there certain containers that are best for fermenting vodka?

The best containers for fermenting vodka are those that are food-grade quality, such as glass, stainless steel, or certain types of food-safe plastic. These materials do not react with the fermenting liquid and are easy to clean and sanitize.

Can I make vodka without any special equipment?

It is highly advised to use specialized equipment when making vodka for safety reasons and to ensure the purity and quality of the spirit. Basic distillation requires a still, and manufacturing a safe and functional still at home can be challenging and illegal in many areas without proper permits.

How does the source material affect the taste of vodka?

The source material can impart subtle flavors and characteristics to the vodka. For example, wheat-based vodkas are often smooth and slightly sweet, while potato-based vodkas can have a creamier texture. The distillation and filtration processes aim to minimize these differences, resulting in a clean and neutral spirit, but some nuances can remain.